TRUSTED BY FABRICATORS - AUSTRALIA WIDE

For over 40 years MACC has been Australia's leading range of Italian made metal cutting saws.These machines are specifically designed for high volume continuous use in the most demanding manufacturing workshops.

Each machine is guaranteed to produce precision cutting results and includes state-of-the-art features that make the metal cutting process easier than ever.

WHY CHOOSE MACC

Italian made quality, for the professional

Extensive Range

40 years of Development

Ongoing Service & Support

Dealer Network Australia Wide

What our customers say

Modnpods

Who use our MACC 335MS Bandsaw

"Modnpods are in the business of building small studio homes that are environmentally friendly. Each Modnpod is architecturally designed and manufactured on the Gold Coast using 90% Australian premium materials, with 70% of those fully recyclable at the end of their life. Currently Modnpods has installed one of our MACC 335MS bandsaws.

What our customers say

SILO DEVELOPMENTS

Who use our MACC 650 DI Bandsaw

Silo Developments Australia Pty Ltd has more than 20 years experience in steel fabrication and installation with an extensive track record aligned with most T1 Infrastructual Construction companies in NSW.

When cutting through steel for its primary role, Silo Developments Australia rely on the quality of the MACC 650 DI and MACC cutting fluid. The MACC superior quality and invoative product range delivers the performance and value that is demanded in this heavy steel manufacturing application.

DEMONSTRATION VIDEOS

DEALER NETWORK AUSTRALIA WIDE

Purchase MACC Metal Working Saws from your local industrial supplier or tool shop. The on-going service and support is provided through your local dealer meaning the best local service is always provided.

OUR MAJOR DISTRIBUTORS

PRODUCT INFORMATION

Coldsaws are an essential cutting tool used in most metal workshops thanks to the accurate and high-quality cut produced. These circular sawing machines are ideal for most metal cutting operations, and work bycutting metal plates at a low RPM, reducing friction and heat to deliver a fast, clean cut.

These metal cutting saws are fast and will cut all types of materials accurately. The blades used in coldsaws transfer the energy and heat created in the cutting process to the chip, thus resulting in the blade and work metal remaining cold – hence the name ‘coldsaw’.

Coldsaws can machine most ferrous and non-ferrous alloys. The blades on coldsaws can also be reused and sharpened when they become blunt. In fact, coldsaw blades can be sharpened up to 40 times!

Coldsaws are known for delivering an accurate and clean cut direct from the machine, so if a quality cut is what you are looking for, the coldsaw is an excellent choice.

Bandsaws are considered to be capacity-type cutting machines, making them great for large volumes of work.

Featuring a horizontal blade, the cut quality is good on bandsaws, however, do keep in mind that burr does tend to be left on the edges. The blades on bandsaws are also disposable, so you can throw away an old and blunt blade and replace it with a new one with zero hassle.

Friction saws are high-speed circular saws where frictional heat is used to melt the material adjacent to it. The heat formed from the friction is sufficient enough to melt the metal, producing a very fast cut.

Friction saws are specially designed for cutting the most difficult materials at high speed and are ideal for simple straight-line sawing or stock cut off. Circular friction saws are regularly used to cut structural steel shapes, products and structural beams. From thin tubes to hardened steel bars, a friction saw can do it all. Keep in mind that due to the high speed of these saws, the blades have a shorter life span compared to other metal saws.

T.C.T. stands for tungsten carbide-tipped. This refers to the type of blade used by this cutting saw. T.C.T. blades are made from alloy steel with the tips of the teeth brazed with tungsten carbide inserts. These blades can operate at much higher temperatures than standard coldsaw blades, which means they can be run at much higher surface speeds to produce a faster cut while also maintaining an acceptable chip load per tooth.

T.C.T. saws are ideal for cutting non-ferrous metal including aluminium, copper, and brass. A T.C.T. saw will give you better value for money as well as a faster, cleaner cut when working with these materials.

T.C.T. blades and saws hold a very long wear life and superior cutting performance, however, they are less resistant to shock. This is why MACC have manufactured T.C.T. saws specifically to suit these blades that deliver reduced vibration during the cutting process.

We stock bandsaw blades to suit every MACC bandsaw model available. We have over 50 varieties in the range with various lengths, widths and number of teeth.

These straight, horizontal blades are ideal for general purpose cutting, and blade types are available to suit all bandsaw models we have in stock.

Synthetic metalworking fluid designed for use with most coldsaws, bandsaws, & metal working machinery.

MACC MACHINERY AUSTRALIA

With over 40 years in the saw manufacturing industry, MACC is internationally renowned for it’s superior quality and innovative product range. This premium range of Italian made metal cutting saws includes bandsaws, coldsaws, friction saws and T.C.T saws. MACC machines are specifically designed for very high volume, continuous use in the most demanding manufacturing environments.

MACC Australia specialise in supplying industrial metal cutting bandsaws, coldsaws, friction and TCT saws that deliver the highest quality cuts and meet the high quality and capacity demands of industrial applications.

As metal cutting saw specialists, we have been supplying bandsaws to industrial workshops all across Australia for over 20 years. Our experience and expertise has helped us to develop Australia’s best range of metal cutting saws and allows us to deliver the best service and advice to our customers.

MACC saws are available Australia wide through our network of distributors. Contact us today for pricing and distributor information.

WHY CHOOSE MACC MACHINERY

Italian-Made – Italian-made machinery is the best in the world and MACC is no exception. Extensive time and effort is put into manufacturing highly effective, top quality metal cutting machines that meet industry demands. Manufactured in Italy, each machine is guaranteed to produce excellent cutting results and include state-of-the-art features that make the metal cutting process easier than ever.

40 Years’ Experience – With decades of experience and expertise in the industry, the MACC brand is reliable and their metal cutting saws are up to the task. The longevity of this brand proves that MACC has been able to adapt to the changing needs of the industry and continues to exceed expectations in both quality and price.

Metal Cutting Saw Specialists – When you know what you excel at, you stick with it. MACC has the know-how to manufacture high performing metal cutting saws for the construction and manufacturing industries, which is why they specialise in this particular type of machinery.

METAL CUTTING SAWS

MACC are experts at manufacturing every kind of saw needed in the metal working and fabrication industry with manual, semi-automatic and fully automatic options available. With robust industrial-grade construction and superior cutting quality, MACC is top of the line.

We have all types of metal cutting saws in our range including:

Coldsaws – Circular saw machines that produce a fast, accurate and high-quality cut. Both the blade and material being cut remain cool when a coldsaw is used. They are well suited to cutting most ferrous and non-ferrous alloys and the blades can be sharpened multiple times when they become blunt.

Bandsaws – Buy Australia’s most trusted quality bandsaws. Well suited to high capacity metal cutting jobs, these bandsaws can cut through large volumes of work quickly and easily. The M42 bandsaw blades provide excellent life and are considerably cheap, meaning the cost per cut is very low. When blade become blunt, they can easily be replaced.

Friction Saws – High-speed circular saws that use frictional heat to cut through metal. The heat generated melts through the metal, delivering a very fast cut. Friction saws are often used for cutting the most difficult materials, however, the blades do have a shorter life span than other saws.

T.C.T. Saws – A fast and precise circular saw that specifically suits non-ferrous metals such as aluminium, copper and brass. A tungsten carbide-tipped blade is used in these saws which provides superior strength and allows the saw to be operated at much higher temperatures to produce a faster cut.

SAW BLADES

We have MACC bandsaw and coldsaw saw blades that are ideal for general purpose cutting as well as specialised saw blades for the toughest metal cutting jobs.

Our range includes speed face coldsaw blades which reduce friction and increase wear resistance as they cut. Cobalt coldsaw blades are another superior option featuring 5% cobalt content that enhances the hardness of the blades, making them an optimal choice for cutting hard materials that reach higher temperatures during the cutting process.

We also stock T.C.T. saw blades which are tungsten carbide-tipped for superior cutting quality when working with non-ferrous metals.

SAW ACCESSORIES

We have the essentials you need in our Saw Accessories section. No cutting saw is complete without synthetic metal working fluid – we sell general metal and aluminium particular working fluid in 5 litre and 20 litre capacities. We also sell stands to suit your MACC coldsaw, giving you the ideal working platform at a comfortable height to complete your metal sawing work.

MACC CATALOGUE

Our catalogue gives you full details on each cutting saw all in one place, allowing you to compare product features and benefits side by side. Our catalogue can be viewed online, saved directly to your PC or printed out. In it you will find all the specifications for every product we stock.

CHOOSE MACC MACHINERY FOR METAL CUTTING SAWS

If you’re looking for the biggest range of metal cutting saws with the widest variety of cutting capacities, MACC Machinery has a machine to suit. We distribute every product listed on our website throughout Australia, New Zealand, South East Asia and the South Pacific. MACC products are can be viewed at any of our distribution warehouses or distributors shops Australia wide including Sydney, Melbourne, Adelaide, Brisbane, Tasmania and Perth.

If you have any questions about our Italian-made saws, blades or accessories, or if you would like a quote or are ready to buy, contact us directly on (07) 3287 1114.

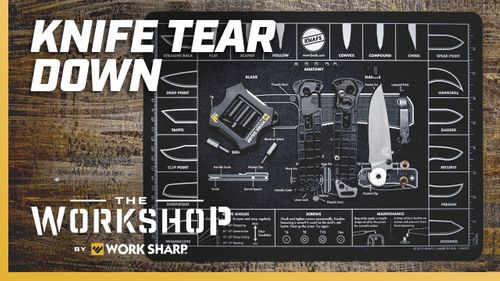

Learn

#worksharptools

-

Sharp scissors, smooth cuts: How to sharpen your scissors at home

05-02-2024Sharp scissors, smooth cuts: How to sharpen your scissors at home Read More... -

-

-

-

-

Elite vs elite - Which sharpener is best?

05-02-2024The Precision Adjust Elite and the Ken Onion Elite face off in a rigorous head-to-head test, evaluating these high-end knife sharpening machines. Read More... -

Electric knife sharpening blets wear out. When to replace them?

05-02-2024Here are a few indicators to help you recognize when your belt is wearing down and may be due for replacement. Read More... -

How to Sharpen a Hunting Knife

05-02-2024Every hunter anticipates a successful season, putting in the necessary preparation to ensure everything unfolds according to plan, leading to a rewarding harvest. Read More... -

-

MACC

Superior quality and an innovative product range are the reason MACC is an internationally renowned brand with over 40 years in the saw manufacturing industry. Made in Italy, this premium range of metal cutting saws includes cold saws, friction saws, T.C.T saws and bandsaws that are ideal for use in the most demanding manufacturing environments and are designed specifically for very high volume, continuous use. ITM is your metal cutting saw specialists in Australia

MACC METAL CUTTING SAWS

MACC are experts at manufacturing every kind of saw needed in the metal working and fabrication industry with manual, semi-automatic and fully automatic options available. With robust industrial-grade construction and superior cutting quality, MACC is top of the line quality metal cutting machines.

We have all types of superior metal cutting saws in our range including:

MACC Coldsaws – Circular saw machines that produce a fast, accurate and high-quality cut. Both the blade and material being cut remain cool when a coldsaw is used. They are well suited to cutting most ferrous and non-ferrous alloys and the blades can be sharpened multiple times when they become blunt.

MACC Bandsaws – Well suited to high-capacity metal cutting jobs, bandsaws can cut through large volumes of work quickly and easily, however, the cut is slightly less clean and precise than some other metal cutting saw options. When bandsaw blades become blunt, they will need to be replaced.

MACC Friction Saws – High-speed circular saws that use frictional heat to cut through metal. The heat generated melts through the metal, delivering a very fast cut. Friction saws are often used for cutting the most difficult materials, however, the blades do have a shorter life span than other saws.

MACC T.C.T Saws – A fast and precise circular saw that specifically suits non-ferrous metals such as aluminium, copper and brass. A tungsten carbide-tipped blade is used in these saws which provides superior strength and allows the saw to be operated at much higher temperatures to produce a faster cut.

MACC SAW BLADES

We have MACC bandsaw and coldsaw saw blades that are ideal for general-purpose cutting as well as specialised saw blades for the toughest metal cutting jobs.

Our range includes speed face coldsaw blades which reduce friction and increase wear resistance as they cut. Cobalt coldsaw blades are another superior option featuring 5% cobalt content that enhances the hardness of the blades, making them an optimal choice for cutting hard materials that reach higher temperatures during the cutting process.

We also stock T.C.T saw blades which are tungsten carbide-tipped for superior cutting quality when working with non-ferrous metals.

MACC SAW ACCESSORIES

We have the essentials you need in our Saw Accessories section. No cutting saw is complete without synthetic metalworking fluid – we sell general metal and aluminium particular working fluid in 5 litre and 20-litre capacities. We also sell stands to suit your MACC cold saw, giving you the ideal working platform at a comfortable height to complete your metal sawing work.